Description

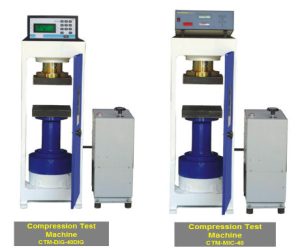

Compression Machines Digital Compression Testing Machine : CTM-DIG-40DIG BS 1881-115, BS 1610 The Digital Compression Testing Machine has been designed to meet the need for a simple, economic and reliable means to test concrete for its compressive strength. The design emphasizes simplicity, both of construction and operation, and makes the machine easy to use and maintain. The unit is compact, making its useful for site applications. The digital machines are provided with a pace rate indicator to indicate pace rate on a Bar Graph. With a little experience, the pace rate can be manually adjusted while the test is in progress. The Complete Unit comprises of: Loading Unit: The loading unit is of fully welded construction having a cross head, base and solid plates. The hydraulic jack is fixed to the base. The platens of the machine are hardened, ground and polished. The upper platen is provided with self-aligning action. To facilitate testing of various size specimens, suitable size spacers are provided complete with ball seating arrangement. Pumping Unit: The two-speed pump facilitates rapid approach of the platens for day light closure and also provides comprehensive control over the application of load. A control valve provides fine control over the loading rate for accuracy of pacing. The digital read-out unit, incorporates a 4-digit display, calibrated in kN and features integral load pacing in kN/sec. Maximum load is held and retained for approx. 15 min, unless cancelled, using the panel mounted reset switch. Pace rate set for running the test can be maintained manually with the help of a bar graph indicator. Logged data printing facility through a parallel port interface is provided in the machine. Readings up to 100 complete runs/tests can be stored in the memory. Micro Controller Based Compression Testing Machine : CTM-MIC-40 BS 1881-115, BS 1610 Operation of Micro Controller based Compression Testing Machine are controlled by an intelligent Pace Rate Controller. This facilities Automatic Pace Rate Control, Data Logging, Data Printing, Load Hold etc. It has a full 3 term PID feedback control which uses a high torque Stepper Motor. It consists of a Loading Unit, an Electrically Operated Hydraulic Pump and an Intelligent Pace Rate Controller. Micro Controller based Compression Testing Machine is available in all models from 50kn to 3000kN capacity. In addition to all the features of Compression Testing Machine with digital display, this machine has automatic pace rate control with the facility of data logging, storage & printing for analysis. The operation of the machine is detailed in the operating manual supplied with the machine. The operation is user friendly with a menu driven interface and prompts for an operator. Loading Unit: The loading unit is of fully welded construction having a crosshead, base and solid side plates. The hydraulic jack is fixed to the base. the platens of the machine are hardened, ground and polished. The upper platen is provided with self-aligning action. To facilitate testing of various size specimens, suitable size spacers are provided compete with ball seating arrangement. Pumping Unit: The pumping unit has two speeds. It can pump oil from an oil reservoir, fitted with an oil filler plug-cum-dipstick and a drain plug. The pump is driven by an electric motor which has to be connected to 220 Volts, Single Phase, 50 Cycles A.C. Supply through a junction box provided for the purpose, at the back of the pumping unit. The unit further contains two programmable motors for pace rate control and the opening and closing of the release valve. It is also provided with manual release to be used in case of a power cut or any other emergency. Special Features: 1. Automatic Pace Rate Control at a preset value. 2. Automatic Data Logging. 3. Logged Data Printing Facility. 4. Data Storage for upto 150 runs. 5. Multifunctional LCD interface. 6. Menu Driven interface. 7. Auto Shut down facility. 8. Load hold facility. 9. Manual emergency stop button. 10. Peak load record. 11. Bar Graph Display for on-line monitoring of the quality of control. 12. Automatic control of the pump motor. 13. Automatic display of breaking load at the end of the test. 14. Real Time Clock to keep automatic track of the date, time and runs. 15. Calibration checking facility. 16. Support for an additional compression or flexure units (optional). Automatic Compression Testing Machine : CTM-AUTO-40 The Automatic Compression Testing Machine is a fully automated version of the manual / semi-automatic Compression Testing Machine. The machine is available in 500kN, 1000kN, 2000kN, 3000kN, 5000kN Ranges. It has provision for automatically turning the pump on and off, controlling the set pace rate and switching the machine off under predetermined conditions. The Control release the pressure at the end of every run and reinitializes the machine at the beginning of every test. The pace rate is maintained by means of full three term PID feedback control using high torque stepper motors and drivers sets. Data acquisition, storage, management and analysis are all fully automated. The load resolution is for is 0.1kN for machines up to 1000kN capacity & 1.0kN for the 2000kN, 3000kN & 5000kN Machines. The complete unit comprises of: Loading Unit: The loading unit is of fully welded construction having a cross head, base and solid side plates. The hydraulic jack is fixed to the base. The platens of the machine are hardened, ground and polished. The upper platen is provided with self-aligning action. To facilitate testing of various size specimens, suitable size spacers are provided complete with ball seating arrangement. Pumping Module: This has a two-speed hydraulic motor driven pump and a bonded strain gauge-based pressure transducer. Digital Head: This contains all the electronic system for controlling the pace rate, acquiring and storing test-data, communicating with the computer and operating the load-release motor. RS 485 to RS 232 Convertor: This converts data transmitted by the digital head to a form recognized by the computer. The system is compatible with any computer with the following: Specification: P-IV and above, 1.9Ghz 256 Mb RAM Intel Chipset with on-board graphics card. 40 GB HDD 1.44MB FDD & CD ROM DRIVE Standard Keyboard 1 Serial Port 1 Parallel Port Printer HP 5550 or latest UPS APC 500 VA or equivalent Compression Testing Machine (Pillar Type Load Frame) Hand Operated: CTM-M4C-44HO IS 516, BS 1881. These are four pillar type load frames. Four solid pillars are vertically fixed to a sturdy base and at other end is fixed a cross head. The height of the cross head is also slightly adjustable. A gauge 200mm is fixed in the centre of cross head. To the lower end of this lead screw is fixed upper platen with a spherical seat for self alignment. At the centre of the base plate is fixed a jack, on the top of which the lower platen with the help of a centering pin is kept. The distance between the upper and lower platen is variable by means of the lead screw. A spacer block is also supplied with the load frame. This spacer block which can be fitted on the top of the jack and below the lower platen by means of centering pins helps reduce the distance between the two platens. The platens are well machined, polished and hardened. The lower platen has concentric grooves to centrally place the specimen. A dust cover for jack is supplied to prevent any going in the jack. Ranges: 50kn to 3000 kn Compression Testing Machine: CTM-SA-50ZI 2051 Range of Semi-Automatic concrete compression machines give users the ability to test and analyse concrete samples in accordance with all major international standards. The power pack incorporates a durable variable output pump, allowing fine control for accurate load pacing, or maximum pump output for daylight closure. The rapid approach pump provides a high rate of daylight closure and is available as an optional extra for the motorised power pack- only if fitted at the time of ordering. An onboard LED screen allows the sample load / Stress to be monitored. The control panel allows for data input and manual control if required. Testers are manufactured in the range of 300 kN - 5000 kN capacities. The standard models are of 1150 kN, 2000 kN and 3000 kN capacity. Suitable for testing 50mm, 100mm, 150mm and 200mm cube samples as well as cylinder samples with 75 160mm diameter and 150-320mm height. Pressure safety valve, piston limit switch, removable front and rear gates are standard in all models. Upper compression platens have ball seating assembly for movement in all models. All compression platens have a surface hardness of 55 HRC. Required distance pieces of 100mm, 50mm and 20mm for vertical test distance are supplied as standard in all models. Pressure transducer with a sensitivity of %0.3 is used for load measurements. All models operate with 220-240 V AC, 50 60 Hz, 1 phase mains power. Compression Testing Machine (Channel Type Load Frame) Hand Operated: CTM-CH-40HO IS 516, BS 1881 In these load frames “C” channels are used, they are welded at the top as well as bottom and with stand high loads. A hydraulic jack is fitted at centre of the base of the load frame, over which can be fitted lower platen and spacer block with the help of cantering pin. A lead screw passes through the top of the frame. To the lower end of this lead screw is fixed the upper platen with spherical seat for self-alignment. The platens are accurately machined, hardened and polished. The lower platen grooves to correctly place the specimen. Note: The platens are normally rectangular on shape, but no special request square platens or circular platens can be supplied at an extra cost. Ranges: 50 kN to 3000 kN Compression Testing Machine (Four Pillar Nut Model) Hand cum Electrically Operated: CTM-4PN-40 IS 516, BS 1881. The load frame is made up of high-quality steel construction with a fixed. Upper lead carrying a ball seated platen. 4 pillars are fixed to the base and the top plate of the loading frame. The upper and lower plates are adjusted with the help of head screw on either side of the pillar. The ram dia of the machine varies from the requirements of the customer. The lower pattern are at the base of the frame above the ram and it is rectangular in shape. Sufficient clearance is provided between the platens to fit in the cylindrical/ cube moulds. Spacer provided to adjust cubes and cylinders. A 20 cm dia pressure gauge with maximum load induction pointer is fitted on the top panel and in turn is connected to the hydraulic pressure pipe. On the right hand a console is fitted within which the electrical motor is fitted alongwith its coupling which in turn is connected to the pumping unit. A slow / fast loading rate regulator fixed on the top of the console for adjusting the rate of loading. The machine is duly calibrated and passed after inspecting and analysing it with a compression level indicator is provided as a dip stick. Optional: 1. Extra gauges can be attached to the machine (max. 3nos.), for better accuracy and results. 2. Electrical connection can either be Single Phase on 220 V A.C., or Three Phase 440 V A.C. 3. Rectangular plates of various sizes on request.